1. The product has the same processing performance as the log. It can be nailed, drilled, cut, bonded, and connected and fixed with nails or bolts. The surface is smooth and fine, without sanding and painting. The paint adhesion is good, and it can also be painted according to personal preferences.

2. The product has better physical properties than the log, better dimensional stability than the wood, and will produce cracks, warps, no wood knots, and twills. The colorful products can be made by adding colorants, films, or composite surfaces, so there is no need for regular maintenance.

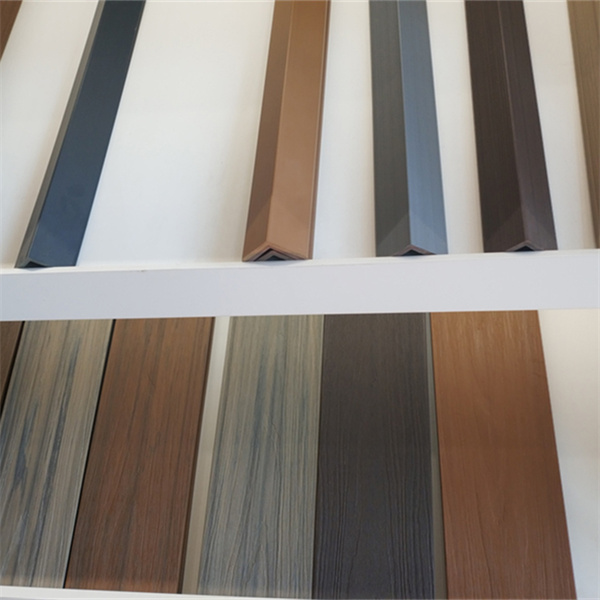

3. Be able to meet the needs of various specifications, sizes, shapes, thicknesses, etc., which also includes providing a variety of designs, colors and wood grain finished products, giving customers more choices.

4. The product has such excellent properties as fire prevention, water resistance, corrosion resistance, moisture resistance, no moth eaten, no fungus, acid and alkali resistance, no poison, no pollution, and low maintenance cost.

5. The product has a similar wooden appearance, higher hardness than plastic, long service life, thermoplastic molding, high strength and energy saving.

6.The product is firm in quality, light in weight, heat preservation, smooth and flat in surface, free of formaldehyde and other harmful substances, and free of toxicity and pollution.

Co extruded wood plastic profile is a popular product in recent years. It is manufactured by the best extrusion forming technology in the industry. Different abrasives are used to extrude a variety of fabrics at the same time, and it is mixed and formed at one time. The co extruded wood plastic board has one more layer of protective layer thickness than the ordinary wood plastic board, which is more wear-resistant, scratch resistant, dirt resistant, crack free and mildew free. Therefore, the co extruded wood has become the main material for outdoor floors.