This week, we visited the co-extrusion wall panel factories ,Please follow the photos to visit our factory.

1.Co-extruded Wpc wall panelProduction line display

The granulation process of co-extrusion wall panel material is the process of mixing and granulating wood powder, plastic particles and additives together.Extrusion molding, thermocompression molding, injection molding, and compression molding are the main molding methods for processing wood-plastic composite materials.

2.co-extruded decking Wpc indoor wall panel Production line display

The main learning content of this production line is the process of laminating. The indoor wall panels can be selected in different colors according to the needs of customers.

3.Wpc wall panel board outdoor Production line display

For the outdoor, this production line mainly demonstrates the embossing process of the outdoor floor, and then it is polished, and the polished floor will become rough, so as to achieve the anti-slip effect.

4.Packaging of WPC wall panels

Workers will arrange the processed boards neatly and pack them.

The indoor co-extrusion wallboards are light and thin, and they are usually packed in cartons, while the outdoor cartons are heavy, and they are usually packed in bubble wrap or woven bags.

Finally, wait for the arrival of the truck, load the container, transport it to the port, and deliver it to the customer

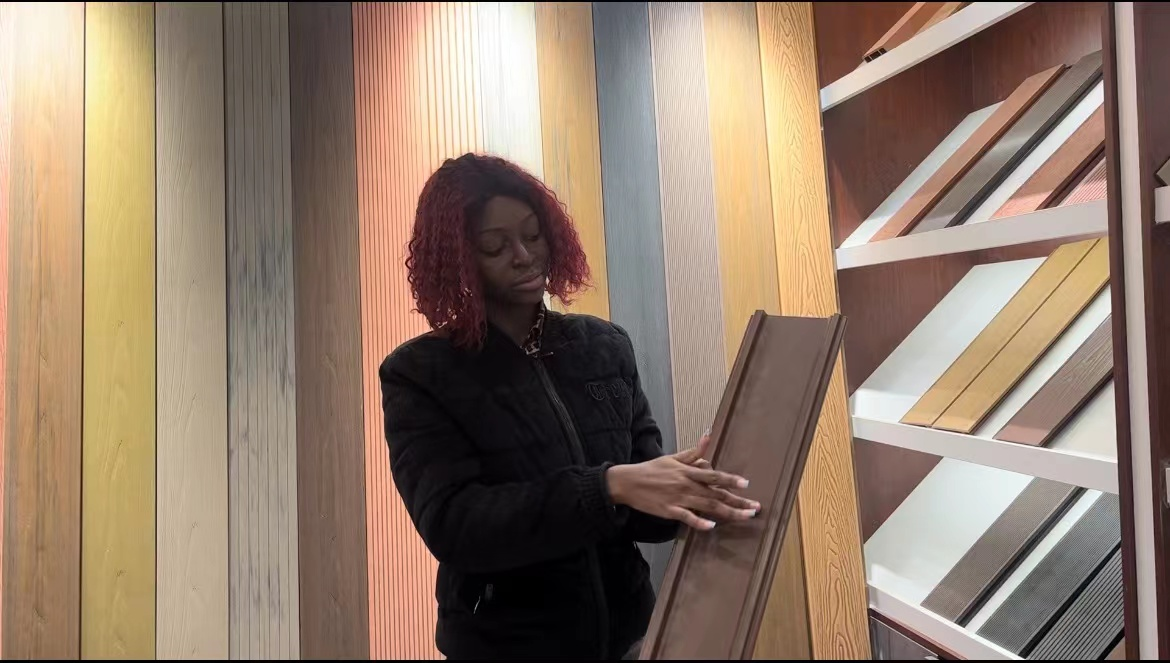

5.Sample room display

We can see the products currently on sale in the sample room, as well as hot-selling products.

6.Future Trend

With the industrialization of wood-plastic composite products, application researchers have discovered the defects of wood-plastic composite products, and users have also put forward higher requirements for them: for garden landscape outdoor products, they must be anti-aging, anti-discoloration, improve Service life; for indoor doors, windows and decorative materials, it must have good flame retardant properties; for building foundation parts, load-bearing wood-plastic products must have high mechanical properties, which need to be strengthened to improve creep resistance. With the improvement of energy-saving calls, the construction industry has also put forward higher requirements for the energy-saving effect of wood-plastic composite products. Therefore, wood-plastic composite products are developing in the direction of functionalization and high added value: flame-retardant, reinforced, anti-aging, creep-resistant, thermal insulation, etc.

Post time: Mar-20-2023