1.Prepare tools and materials:

Tools: art knife, table saw, structural glue gun, level, angle grinder, square ruler, tape measure, triangle file, curve saw, air pump, air gun, cement straight nail gun, mosquito nail gun, electric screwdriver, etc.

Structural glue: used to fix the wall and wallboard.

Timber: mainly used in the structural part of the top light return band.

Woodboard: mainly used in the background wall or ceiling bottoming part.

Corner line: edge trimming at corners.

2、 Installation measurement calculation:

It is estimated that the wall area used for home decoration is 3 times of the floor area, basically including the wall and the top. Only the wall area installed is 2 times of the floor area. The basic installation area is within this area. Accounting method for actual area of household measurement: calculate according to the actual measured area, and basically ensure that the height from the top to the ground is not less than 2.75M after the completion of the light return band, so that after accounting, it can ensure as much as possible to bring unnecessary loss during the installation process.

3、 Calculation of material preparation loss:

Two or three more wallboards shall be prepared for the same wall as loss materials.

4、 Construction steps:

Installation of the wooden structure of the return light trough and the background wall: the wooden structure shall be primed according to the design requirements. Precautions must be taken during the operation. The wooden structure has enough points for the fixation of the integrated wall; The straightness of the batten shall be ensured at the extreme edge; Try to make the right angle and the size of both sides consistent; The structure is relatively firm; After the wooden structure is completed, the actual wiring shall be carried out and the electrical wiring port shall be reserved. Water pipe layout and floor installation.

Ceiling installation: generally, the integrated wall shall be installed from the top during the installation process, and the material section must be straight and free of burrs during the plate cutting process. The higher the cutting saw speed, the less burrs. The measured size must be within the error of 2MM, otherwise the seam will be irregular.

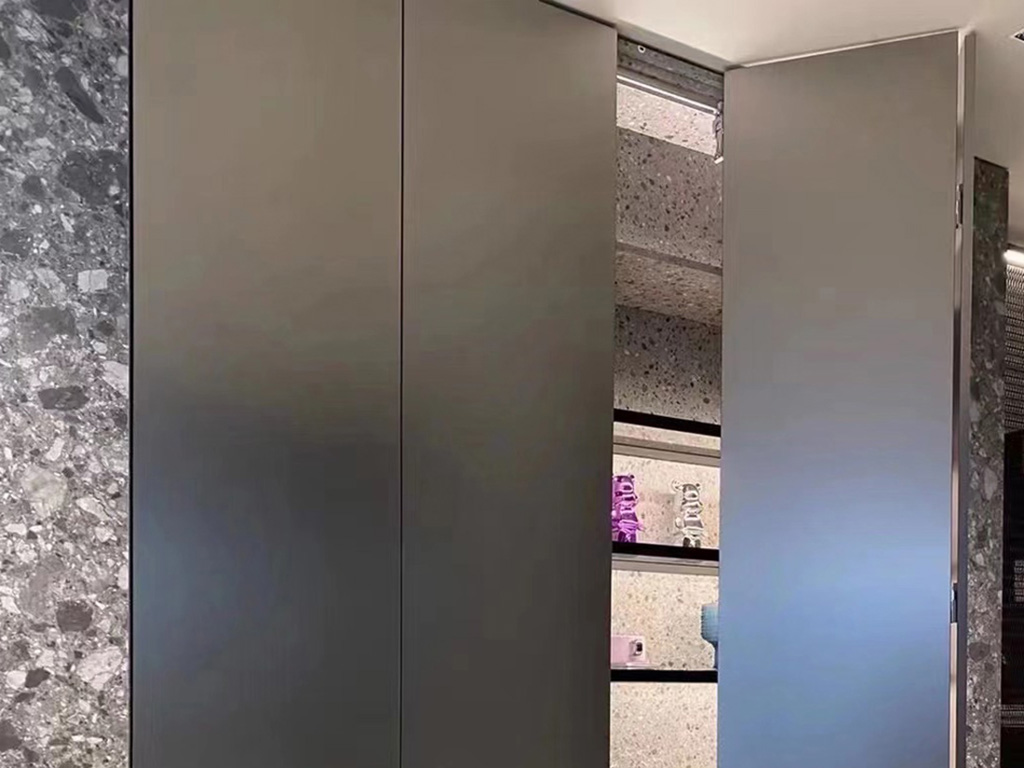

Wall and background wall installation: During installation, if internal corner line, anchor line, waist line, door pocket line, window pocket line, etc. are used, first integrate the wall, and then install the installation line closure.