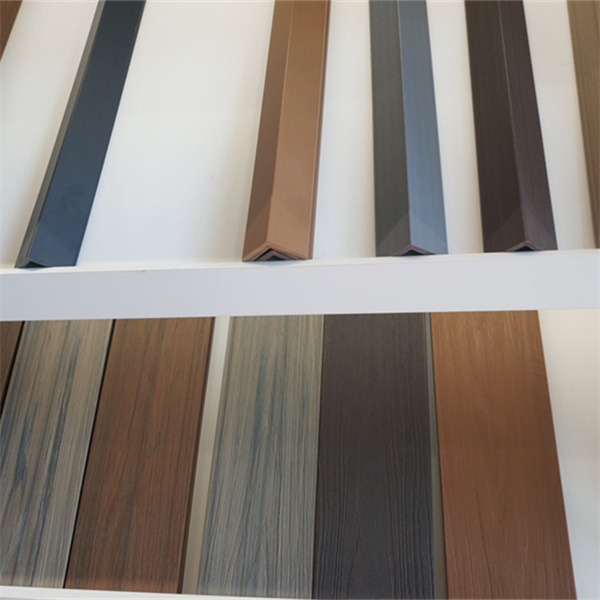

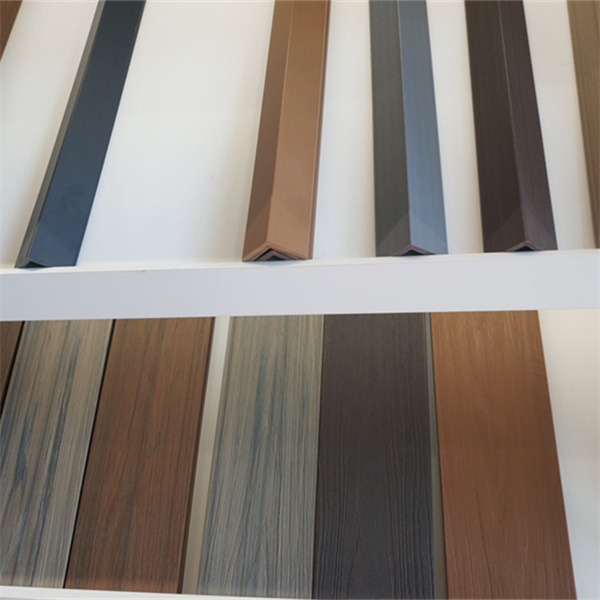

Wood plastic interior doors, skirting lines, integral cabinets, wardrobes, external wall hanging boards, ceiling ceilings, decorative wallboards, outdoor floors, guardrail columns, plastic steel pavilions, garden guardrails, balcony guardrails, fence enclosures, leisure benches, tree pools, flower racks, flower boxes, air conditioning racks, air conditioning shields, louvers, road signs, transport trays, etc.

Wood plastic materials are flexible in application and can be used in any field of wood processing to replace wood as the best environment-friendly materials; Wood plastic products play an important role in the national low energy consumption, and are recyclable products. They are widely used in several major projects in the country.

The foreign wood plastic industry is represented by North America, which is the region with the fastest development and largest consumption of wood plastic composite materials in the world. It is mainly used for outdoor buildings with rough style. Its wood plastic products and manufacturing technology are not very refined. In the past 10 years, the growth rate of the wood plastic market in the United States has remained above 10%, especially in the past 5 years, with the production and sales of wood plastic materials about 700000 tons in 2009. There are about 50 wood plastic enterprises in the United States, which have formed a complete industrial chain. Its characteristics are large scale, high output, and the annual output is generally more than 10000 tons.

Wood plastic industry in China is a very young industry. Its growth history is only more than ten years. No matter from any aspect, it is still young. Compared with the North American market, there is still considerable room for the growth of wood plastic composite materials and finished products in the Chinese market. The design and manufacturing of wood plastic composite materials in China have reached the international advanced level, and many products have been exported abroad.